Phone:

(701)814-6992

Physical address:

6296 Donnelly Plaza

Ratkeville, Bahamas.

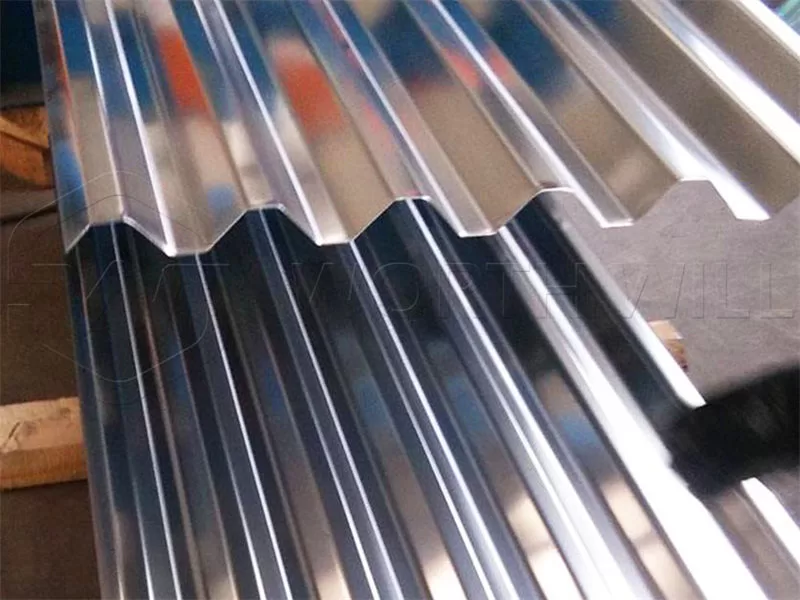

When planning a project, one of the most frequently asked questions is about the corrugated aluminium sheet price. Understanding the factors that influence this cost is essential for effective budgeting and making informed purchasing decisions. Known for its distinctive ribbed profile, which provides enhanced strength and rigidity, this type of aluminium sheet is a popular choice for everything from roofing to wall cladding.

Corrugated aluminium sheet can be classified based on its profile, surface finish, and intended application, all of which can influence its price.

| Classification Type | Details | Impact on Price |

|---|---|---|

| By Profile (Pattern) | ||

| Wave Profile (Sinusoidal) | Classic, uniform wave pattern. Widely recognized for aluminium roofing sheet and simple cladding. | Generally standard, more common profiles can be more cost-effective. |

| Box Profile (Trapezoidal) | More angular, square-shaped ribs. Offers greater strength and span capabilities, popular for industrial buildings. | May be slightly higher due to more complex roll-forming or material efficiency. |

| Tile Profile | Designed to mimic traditional roof tiles, offering an aesthetic appeal. | Often higher due to specialized forming and decorative intent. |

| Other Custom Profiles | V-beam, S-wave, etc., or bespoke designs. | Significantly higher due to custom tooling and lower production volumes. |

| By Surface Finish | ||

| Mill Finish | Untreated, natural aluminum appearance. Most economical. | Lowest cost. |

| Color Coated | Pre-painted with finishes like PE (Polyester) or PVDF (Polyvinylidene Fluoride) for aesthetics and enhanced corrosion protection. Wide range of colors available. | Adds significantly to the corrugated aluminium sheet price, with PVDF being more expensive. |

| Stucco Embossed | Textured surface resembling orange peel, helps hide minor imperfections and reduces glare. | Slightly higher than mill finish due to the embossing process. |

| Anodized | Electrochemical process that thickens the natural oxide layer, enhancing durability, corrosion resistance, and allowing for various colors. | Higher cost due to the specialized treatment. |

| By Application | (While not a direct manufacturing classification, application intent often dictates other specifications like thickness and alloy, thereby influencing cost) | |

| Roofing | Requires good weather resistance, specific profiles for water drainage, and adequate load-bearing capacity. | Price varies with required durability, thickness, and coatings. |

| Wall Cladding | Focus on aesthetics, weather protection, and often insulation integration. | Price influenced by aesthetic finishes, fire ratings, and complexity of installation. |

| Fencing | Emphasizes durability, security, and sometimes decorative appeal. | Generally lower price for standard fencing grades; decorative options increase cost. |

The corrugated aluminium sheet thickness is a primary factor influencing its strength, durability, weight, and, consequently, its price. Thicker sheets use more material and provide greater rigidity and impact resistance.

| Thickness Range (mm) | Typical Imperial (Inches) | Characteristics & Common Uses | Price Impact |

|---|---|---|---|

| 0.3mm – 0.5mm | 0.012″ – 0.020″ | Lighter gauge, more flexible. Suitable for smaller sheds, internal partitions, temporary structures, or areas where light weight is prioritized and structural loads are minimal. | Lower |

| 0.5mm – 0.8mm | 0.020″ – 0.031″ | Common range for standard aluminium roofing sheet and aluminium cladding. Offers a good balance of strength, durability, and cost-effectiveness for residential and light commercial projects. | Medium |

| 0.8mm – 1.2mm+ | 0.031″ – 0.047″+ | Heavier gauge, providing superior strength and rigidity. Ideal for industrial buildings, large-span roofing, areas exposed to harsh weather conditions, or where higher impact resistance is needed. Often uses stronger aluminium alloy. | Higher |

Choosing the appropriate corrugated aluminium sheet thickness is crucial for ensuring the structural integrity and longevity of your project while managing costs.

The specific aluminium alloy used in the manufacturing of the corrugated aluminium sheet significantly affects its mechanical properties and, therefore, its price. Different alloys offer varying levels of strength, formability, and corrosion resistance.

| Alloy Series | Common Alloys | Characteristics | Price Impact | Typical Uses |

|---|---|---|---|---|

| 1000 Series (Pure Al) | 1050, 1060, 1100 | Commercially pure aluminum. Excellent corrosion resistance, high formability, good thermal/electrical conductivity. Relatively soft. | Lower | Basic roofing, flashing, decorative applications where high strength isn’t critical. |

| 3000 Series (Al-Mn) | 3003, 3004, 3105 | Moderate strength, good workability, excellent corrosion resistance. Stronger than 1000 series. 3003 aluminium alloy is very common. | Medium | General purpose aluminium roofing sheet, aluminium cladding, HVAC ductwork. |

| 5000 Series (Al-Mg) | 5005, 5052, 5754 | Higher strength than 1000/3000 series, excellent corrosion resistance, especially in marine environments. Good weldability. | Higher | Marine applications, truck bodies, high-stress roofing, severe weather areas. |

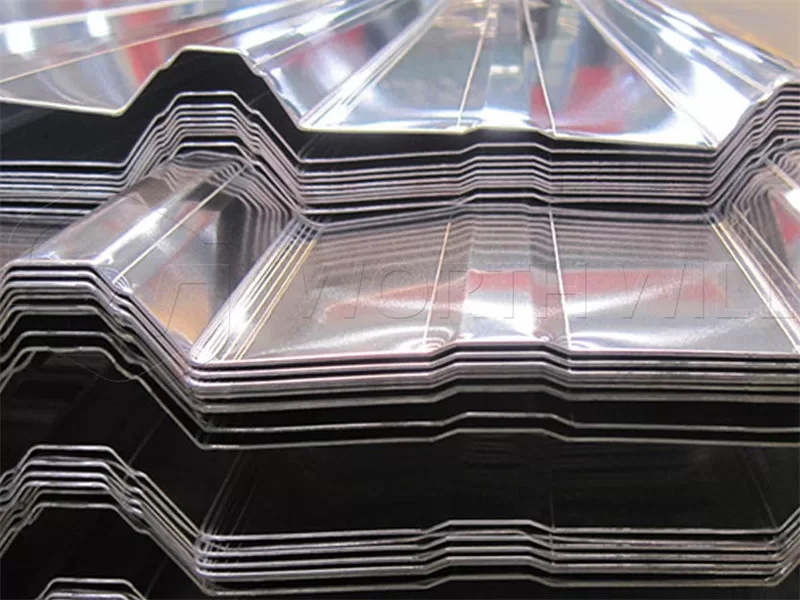

Proper packaging is essential for protecting corrugated aluminium sheet during transport and storage, preventing damage such as scratches, dents, or corrosion. While the packaging itself adds to the cost, it’s a worthwhile investment to ensure the material arrives in pristine condition.

| Packaging Component | Purpose | Price Impact |

|---|---|---|

| Plastic Film/Paper Interleaving | Placed between sheets to prevent surface scratching and damage during stacking and movement. | Minor |

| Kraft Paper/Waterproof Film Wrap | Entire bundles or coils are wrapped in moisture-resistant materials to protect against humidity, rain, and oxidation, especially important for long-distance shipping. | Minor |

| Edge Protectors | Cardboard or plastic protectors placed on the corners and edges to prevent bending or denting during handling. | Minor |

| Steel Strapping | Securely bundles the sheets or coils to prevent shifting, unraveling, and maintain integrity during transit. | Minor |

| Wooden Pallets/Skids | Sheets are stacked on fumigated wooden pallets or skids, facilitating forklift handling and ensuring stability during loading/unloading and storage. | Moderate |

| Wooden Crates/Boxes | For maximum protection, especially for overseas shipping or highly delicate/expensive sheets. Provides a robust outer shell. | Significant |

Reputable suppliers prioritize robust corrugated aluminium sheet packaging to minimize transit damage.

Beyond its price, the enduring popularity of corrugated aluminium sheet stems from its numerous benefits.

| Benefit | Description |

|---|---|

| Lightweight | Significantly lighter than steel or other traditional materials, simplifying installation, reducing structural load on buildings, and lowering transportation costs. |

| Corrosion Resistance | Aluminum naturally forms a protective oxide layer, making it highly resistant to rust and corrosion, even in harsh or humid environments. Excellent for long-term outdoor use. |

| Durability | The corrugation process adds strength and rigidity, making the sheets resistant to denting, bending, and impact. Long lifespan with minimal maintenance. |

| Fire Resistance | Aluminum is non-combustible, offering excellent fire safety properties, making it a safe building material choice. |

| Recyclability | Highly recyclable without loss of quality, contributing to sustainability and potentially offering value at the end of its life cycle. |

| Ease of Installation | Lightweight and easy to cut and form, reducing labor time and installation costs. |

| Aesthetics | Provides a clean, modern, and industrial look. Available in various profiles and color coated finishes to suit design preferences. |

| Thermal Reflectivity | Aluminum reflects sunlight, helping to keep interiors cooler in hot climates, which can lead to energy savings. |

The versatility and beneficial properties of corrugated aluminium sheet make it suitable for a wide range of applications across various industries.

| Application Area | Specific Uses |

|---|---|

| Building & Construction | Roofing (residential, commercial, industrial), Wall Cladding (exterior and interior), Sheds, Garages, Carports, Patio Covers, Ceilings, Partitions, Fencing. |

| Agricultural | Barns, animal shelters, storage facilities, grain silos. |

| Industrial Facilities | Warehouses, factories, power plants, often for roofing, wall systems, and insulation jacketing. |

| Transportation | Truck bodies, trailer linings, bus shelters, shipping containers (though less common than flat sheets, can be used for specific paneling). |

| Decorative & Architectural | Feature walls, artistic installations, modern facades, interior design elements. |

| DIY Projects | Small outbuildings, custom enclosures, garden sheds, general repairs. |

The corrugated aluminium sheet price is not a fixed figure; it fluctuates based on several dynamic factors.

| Factor | Impact on Price |

|---|---|

| Raw Material Costs | The global price of aluminum ingots (the primary raw material) is a major determinant. Fluctuations in the commodity market directly affect the final aluminium sheet price. |

| Manufacturing Process | The complexity of the corrugation process, specific equipment used, and energy costs during production contribute to the overall manufacturing expense. |

| Market Demand & Supply | High demand or limited supply can drive prices up, while lower demand or abundant supply may lead to more competitive pricing. |

| Supplier Location | Sourcing from regions with lower labor costs or more efficient production (e.g., China) can often result in more competitive pricing compared to local suppliers. |

| Order Quantity | Larger bulk orders typically receive lower per-unit prices due to economies of scale in manufacturing and shipping. |

| Customization | Special sizes, unique profiles, or specific color coatings will add to the cost compared to standard products. |

The corrugated aluminium sheet price is a dynamic figure influenced by a combination of raw material costs, manufacturing specifications, market conditions, and chosen alloys and finishes. By understanding these factors, you can make an informed decision that aligns with your project’s budget and performance requirements.

Ultimately, investing in corrugated aluminium sheet offers significant long-term value. Its inherent properties – including being lightweight, corrosion resistant, durable, and fire-resistant – make it an excellent choice for a wide array of applications, from aluminium roofing sheet and aluminium cladding to industrial and agricultural structures. When considering your next building material, the versatility and cost-effectiveness over its long lifespan make corrugated aluminium sheet a compelling option.

To receive an accurate quote, provide the following:

📩 Email your requirement to jane@alroofingsheet.com or contact us via WhatsApp: 008615736973771 .