Phone:

(701)814-6992

Physical address:

6296 Donnelly Plaza

Ratkeville, Bahamas.

Aluminum roofing and curtain wall panels are now a very popular choice in the construction world. Builders and architects love them because they last a long time and look great. When you are looking for a strong and reliable metal roofing material, coated aluminum roofing sheet stands out. It offers excellent protection and a smooth finish for many types of buildings.

One common type is the AA3004 aluminum magnesium manganese alloy. This alloy is well-known for its strength and resistance to corrosion. Using AA3004 alloy for your roof or exterior walls means you get a roofing material that can last for over 50 years. This makes it a smart, long-term investment for any building project.

Choosing aluminum roofing sheet means choosing durability and a modern look. It’s lightweight, yet strong, making installation easier than some other heavy materials. The special coating applied to these sheets adds another layer of protection against weather, UV rays, and pollution, keeping your building safe and looking good for decades.

Aluminum roofing is incredibly versatile. Its strength, light weight, and resistance to harsh weather make it suitable for many different places. The clean look of coated aluminum roofing also fits well with modern architectural designs.

Here are some common places where aluminum roofing sheet and wall panels are widely used:

This wide range of applications shows how flexible and effective aluminum roofing sheet is for diverse construction needs.

Choosing coated aluminum roofing comes with many benefits that make it a top choice for many projects. These advantages go beyond just its good looks.

Here are the key advantages of using aluminum roofing sheet:

These advantages highlight why aluminum roofing sheet is a preferred roofing material for many types of construction, offering both aesthetic appeal and reliable performance for a very long time.

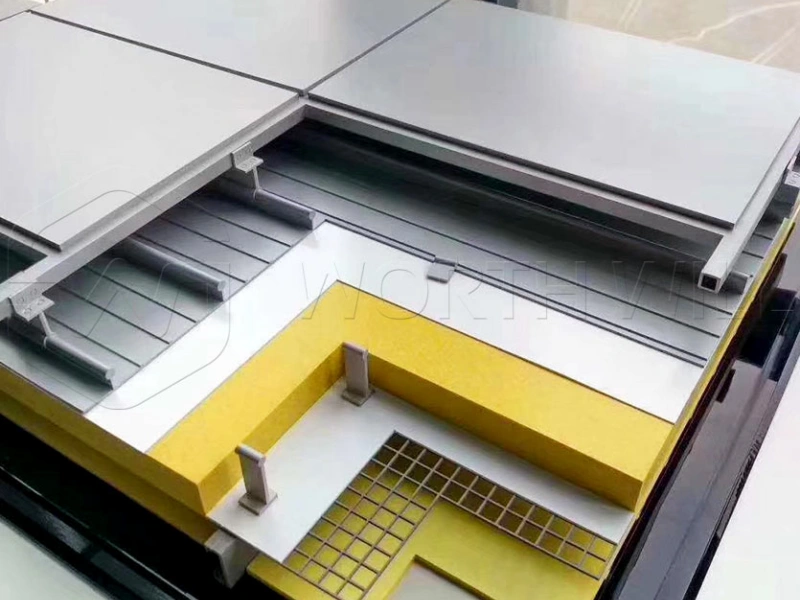

Understanding the specifications is important when selecting the right aluminum roofing sheet for your project. These details help ensure the material meets the necessary standards for strength, durability, and appearance.

Here are typical specifications for aluminum roofing sheet:

| Commodity | Aluminum Roofing Sheet |

|---|---|

| Alloy | 3003/3004 or as per customer’s requirements |

| Temper | H24 or as per customer’s requirements |

| Coating Thickness | customized design |

| Base aluminum sizes | 0.5-1mm or customized |

| Capacity/ Month | 1000 Tons |

These specifications can be adjusted based on the specific needs of your building project. The choice of alloy, temper, and thickness will affect the strength and performance of the metal roofing. Working with a supplier allows you to customize these elements to ensure the aluminum roofing sheet is perfect for your construction.

Many people have questions when considering aluminum roofing for their construction projects. Here are answers to some common questions that might help you decide if coated aluminum roofing is right for you.

While aluminum roofing sheet offers many benefits, there are a few potential downsides to consider. One concern can be the initial cost. Aluminum roof systems can sometimes have a higher upfront cost compared to traditional asphalt shingles, although their long lifespan often makes them more cost-effective over time.

Another factor is potential for noise during heavy rain or hail. However, this can often be significantly reduced with proper insulation installed beneath the metal roofing. While durable, thinner gauges of aluminum roofing sheet could potentially be prone to denting from very heavy impacts, although thicker gauges and the rib design of panels help mitigate this risk.

Also, improper installation can lead to problems, just like with any roofing material. It’s crucial to use experienced professionals for installing your aluminum roof to ensure it performs correctly and lasts for its intended service life.

The cost of a sheet of aluminum roofing can vary quite a bit. Several factors influence the price, including:

Because of these variables, it’s difficult to give a single price per sheet. To get an accurate estimate for your construction project, it’s best to contact a supplier with your specific requirements. They can provide a detailed quote based on the required size, specifications, and quantity of aluminum roofing sheet needed.

Generally, no, you cannot put aluminum roof coating directly over asphalt shingles. Aluminum roof coating products are typically designed for use on metal roofing surfaces. They are formulated to adhere to metal and provide protection against rust, UV rays, and weather on materials like steel or existing aluminum roof.

Asphalt shingles have a granular surface and are not a suitable base for these types of coatings. Applying a coating meant for metal roofing over shingles would likely not adhere properly, could trap moisture, and would not provide the intended protection or performance.

If you are looking to improve the lifespan or appearance of an asphalt shingle roof, there are specific coating products available designed for asphalt shingles. However, if you are interested in the benefits of aluminum roofing, the correct approach is to remove the existing shingles and install a proper aluminum roofing sheet system as your new roofing material.

Stone coated metal roofs are another type of metal roofing that uses a base metal (often steel) covered with an acrylic binder and ceramic-coated stone granules. While they offer durability and a look similar to traditional shingles or tiles, they have some disadvantages compared to coated aluminum roofing:

While a stone coated metal roof is a durable option, coated aluminum roofing offers advantages in terms of weight, potential for granule-free finish, and the specific benefits of the aluminum alloy itself, such as excellent corrosion resistance without needing the stone layer for protection. The best choice depends on the specific needs and aesthetic goals of your construction project.

Choosing coated aluminum roofing sheet provides a long-lasting, attractive, and low-maintenance solution for many building types. Its durability, flexibility, and wide range of finishes make it a preferred roofing material for modern and sustainable construction. Whether for a large airport terminal or a modern home, aluminum roofing stands up to the elements and provides reliable protection for decades.