Phone:

(701)814-6992

Physical address:

6296 Donnelly Plaza

Ratkeville, Bahamas.

Looking for the best aluminium roofing sheet? y understanding the different classification, thickness, alloy, and aluminium roofing sheet design options, you can make an informed choice. As a dedicated factory specializing in aluminium roofing sheets & panels, we are committed to providing top-quality materials and expertise. Contact us today to discuss your project and discover how our products can provide a durable, beautiful, and sustainable roofing solution.

Aluminium roofing sheets are popular for good reasons:

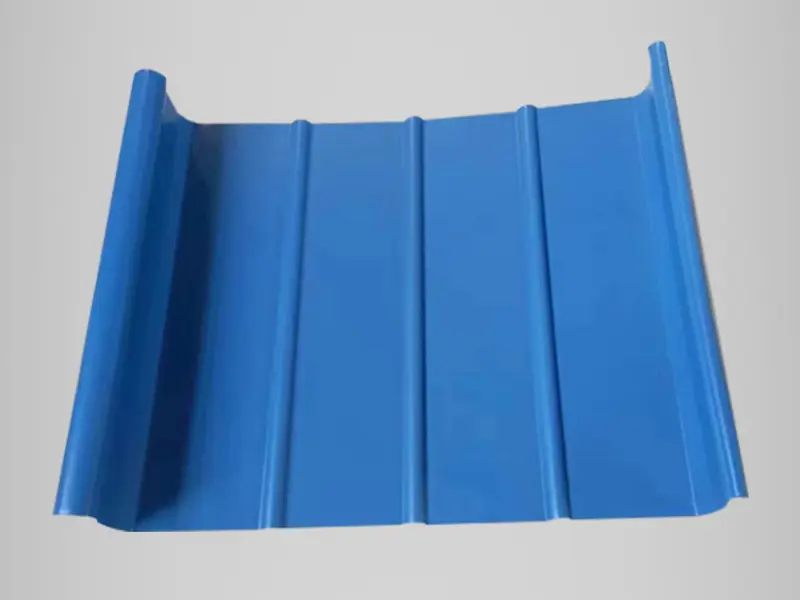

Aluminium roofing sheets come in different profiles and purposes:

| Type | Profile | Best For |

|---|---|---|

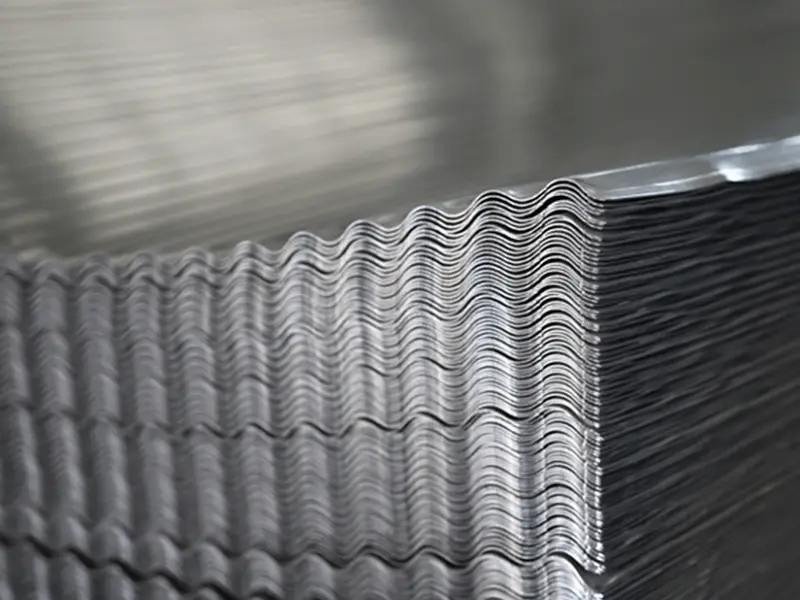

| Corrugated | Wavy pattern | Traditional look, agricultural buildings |

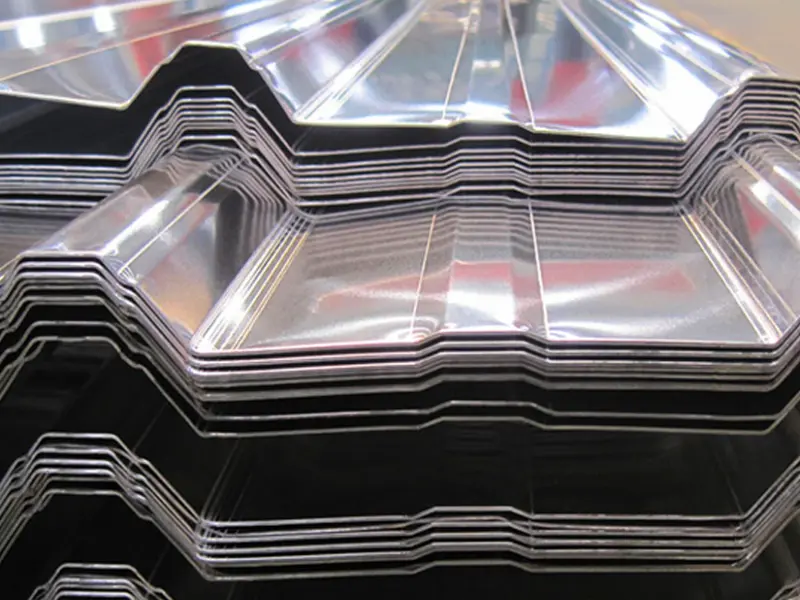

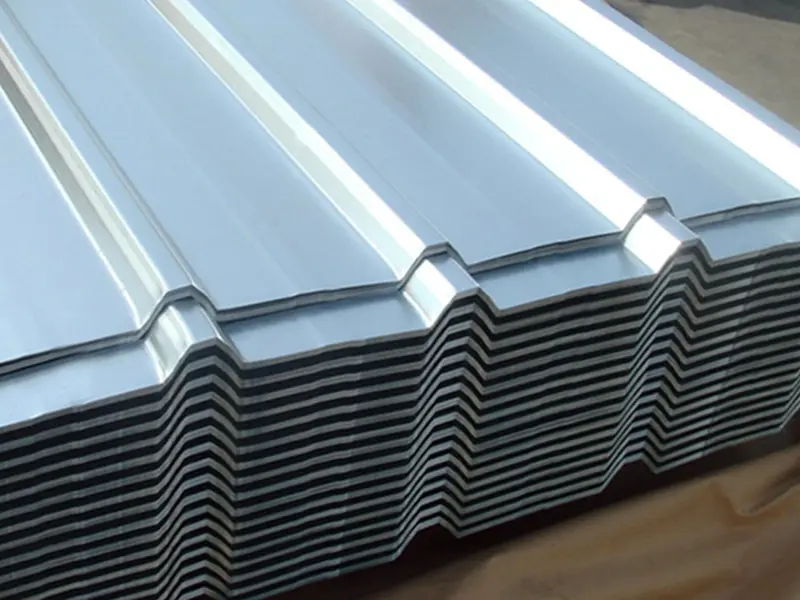

| Trapezoidal | High ridges | Industrial roofs, heavy rain areas |

| Tile-effect | Looks like tiles | Residential roofs, aesthetic appeal |

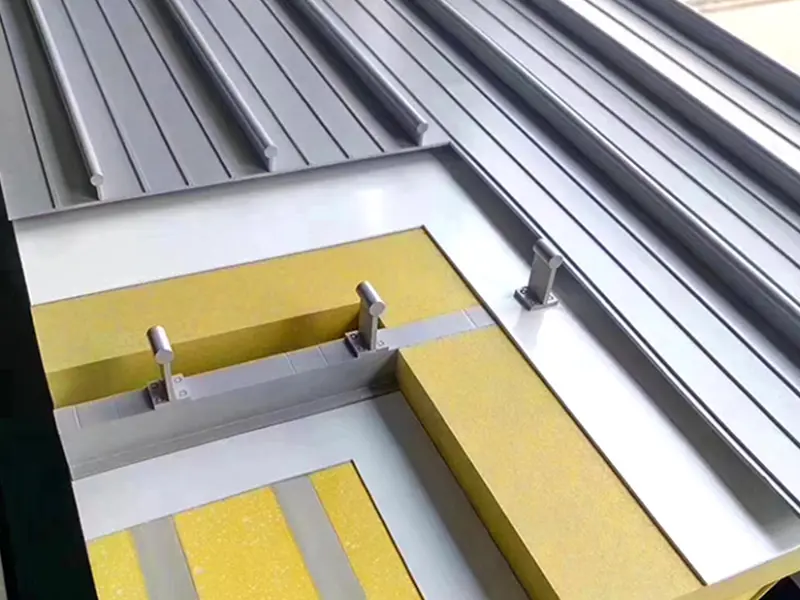

| Standing seam | Vertical joints | Modern architecture, flat roofs |

Choosing the right thickness is crucial for durability:

| Thickness (mm) | Weight (kg/m²) | Recommended Use |

|---|---|---|

| 0.4 – 0.5 | 1.1 – 1.4 | Temporary structures, interior use |

| 0.6 – 0.7 | 1.6 – 1.9 | Residential roofs, light commercial |

| 0.8 – 1.0 | 2.2 – 2.7 | Industrial buildings, high-wind areas |

| 1.2+ | 3.2+ | Special applications, heavy snow loads |

For most applications, 0.7mm thickness offers the best balance of strength and cost.

Different alloys offer different advantages:

| Alloy | Properties | Best For |

|---|---|---|

| 1100 | High corrosion resistance | Coastal areas, chemical plants |

| 3003 | Good strength, formability | General roofing, most climates |

| 5052 | Excellent marine resistance | Coastal regions, high humidity |

| 6061 | High strength, heat-treatable | Special structural requirements |

Modern roofing sheets offer various design features:

Colors and Finishes:

Profiles and Patterns:

Follow this checklist when selecting your roofing sheets:

Our factory produces high-quality roofing sheets with:

Advanced Equipment:

Quality Control:

We ensure your roofing sheets arrive undamaged:

Protective Packaging:

Stacking and Transport:

Q1: Which company’s roofing sheet is best?

A: Look for companies with ISO certification, good warranties, and positive customer reviews. Our factory has 20+ years of experience in aluminium roofing.

Q2: Is aluminium sheet good for roofing?

A: Excellent choice! Aluminium is lightweight, rust-proof, and lasts decades. It’s better than steel in corrosive environments.

Q3: Which roofing sheet lasts longer?

A: PVDF-coated aluminium sheets last longest (40-50 years). They outperform galvanized steel and PVC sheets.

Q4: Which thickness roofing sheet is best?

A: For most homes, 0.7mm is ideal. For industrial buildings, choose 0.8-1.0mm. Thicker sheets last longer but cost more.

Q5: How much does aluminium roofing cost?

A: Prices range from $8-20 per m², depending on thickness, coating, and quantity.

Q6: Can I walk on aluminium roofing?

A: Yes, but use proper safety equipment and walk on the supported areas (where screws are located).