Phone:

(701)814-6992

Physical address:

6296 Donnelly Plaza

Ratkeville, Bahamas.

Among the many materials available, aluminum roofing sheet has emerged as a top contender, offering a compelling blend of durability, aesthetics, and performance. Known for its distinct advantages over traditional options, aluminum roofing is increasingly chosen by property owners and contractors worldwide. But what exactly makes it such a sought-after building material, and what should you consider when investing in it?

| Item | Details |

|---|---|

| Product Name | Aluminum Roofing Sheet |

| Classification | Corrugated / Trapezoidal / Tile Profile |

| Thickness | 0.3mm – 1.5mm |

| Alloy | 1050, 1060, 1100, 3003, 5052 |

| Width | 600mm – 1250mm |

| Length | Customized as per project |

| Finish | Mill Finish / Color Coated / Embossed |

| Packaging | Waterproof paper + Plastic film + Wooden pallet |

Aluminum roofing sheet is classified based on its profile, surface finish, and the type of protective coating applied. These classifications significantly influence both its appearance and performance, as well as the overall aluminum roofing sheet price.

| Classification Type | Details |

|---|---|

| By Profile (Shape) | |

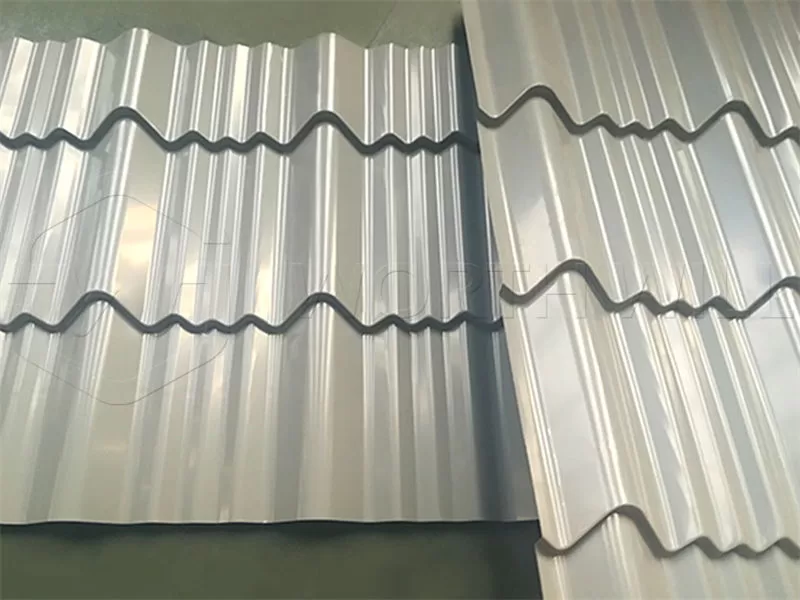

| Corrugated Profile | Classic wave or sinusoidal pattern. Offers traditional look, good drainage, and enhanced rigidity. Widely used for homes, sheds, and commercial buildings. |

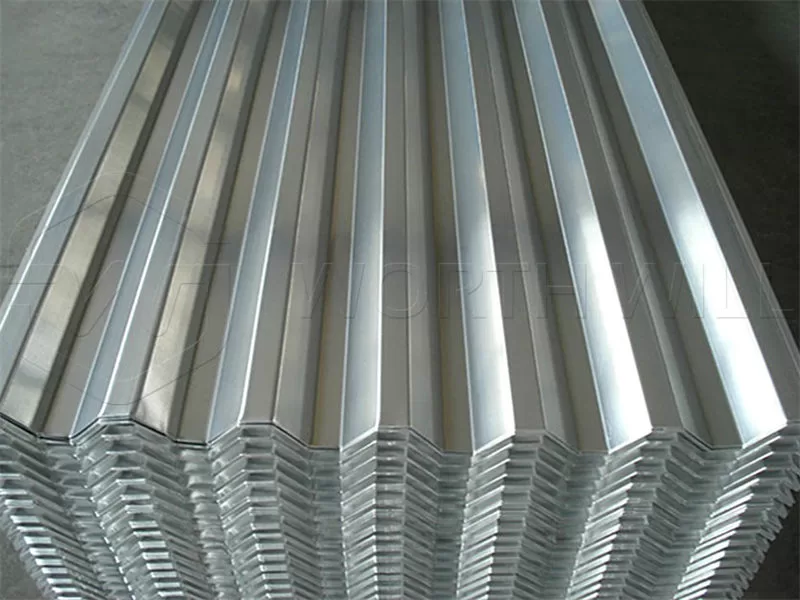

| Trapezoidal (Box) Profile | Features distinct angular ribs, providing superior strength and span capabilities. Popular for industrial and commercial roofing due to its robust nature. |

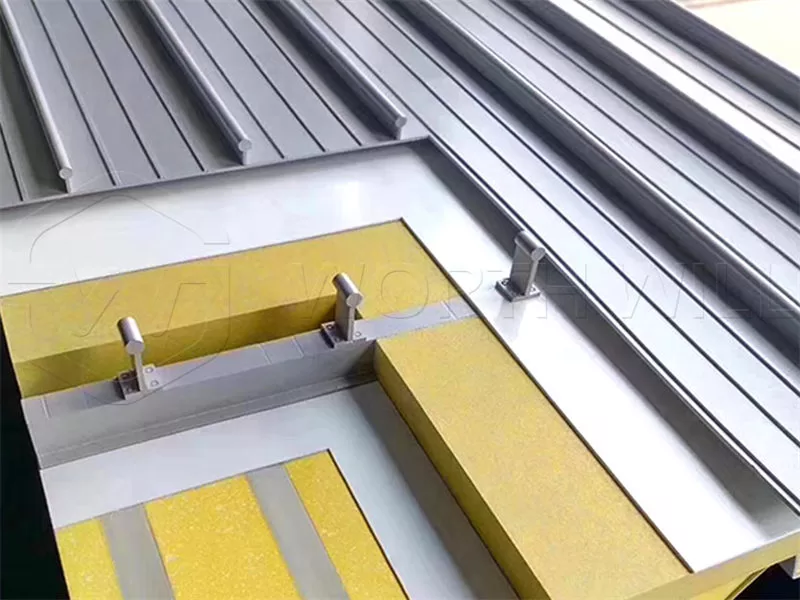

| Standing Seam Profile | Modern, sleek profile with raised seams. Offers excellent leak resistance, often used for architectural appeal in both residential and commercial projects. Provides a clean, contemporary look. |

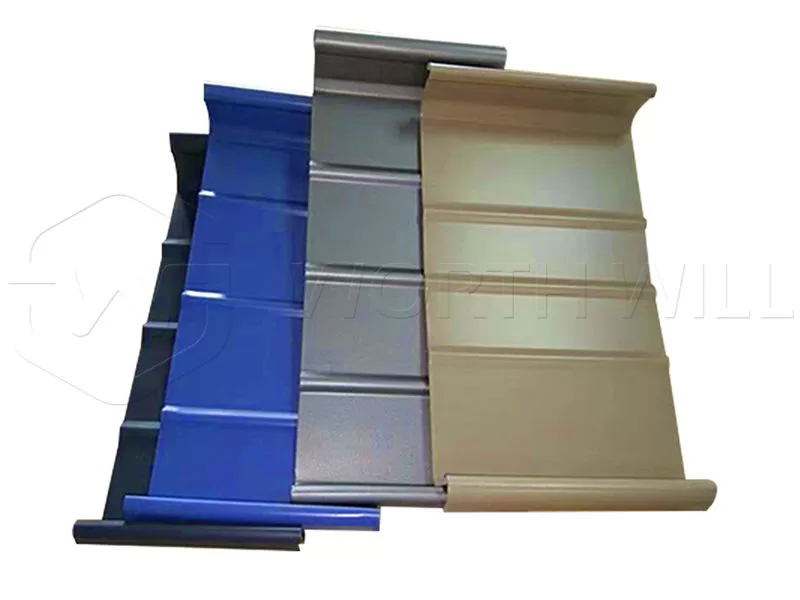

| Tile Profile | Designed to mimic traditional clay or concrete tiles, offering aesthetic appeal without the weight. Often used for residential or resort-style buildings. |

| By Surface Finish | |

| Mill Finish | Natural, untreated aluminum appearance. Cost-effective but can show minor imperfections. |

| Stucco Embossed | Textured surface resembling plaster or orange peel. Helps hide minor surface imperfections and reduces glare. Can be seen on some corrugated aluminium roofing sheet. |

| By Coating Type | |

| PVDF (Polyvinylidene Fluoride) | High-performance, multi-layer coating offering excellent color retention, UV resistance, and corrosion protection. Ideal for long-term outdoor exposure. Leads to a higher price. |

| PE (Polyester) Coating | Good balance of cost and performance for general exterior applications. Offers good color variety but is less durable against harsh UV and weather than PVDF. |

The thickness of aluminum roofing sheet is a critical factor influencing its strength, durability, weight, and, consequently, its aluminum roofing sheet price. Thicker sheets provide greater rigidity and impact resistance, essential for longevity and performance.

| Thickness Range (mm) | Typical Imperial (Inches) | Characteristics & Common Uses | Impact on Price |

|---|---|---|---|

| 0.4mm – 0.6mm | 0.016″ – 0.024″ | Lighter gauge, more flexible. Suitable for smaller structures like sheds, carports, or residential roofs where extreme loads or impacts are not anticipated. Often found in more budget-friendly options. | Lower |

| 0.6mm – 0.8mm | 0.024″ – 0.031″ | Common range for standard residential and light commercial aluminum roofing. Offers a good balance of strength, durability, and cost-effectiveness. A popular choice for corrugated aluminium roofing sheet. | Medium |

| 0.8mm – 1.2mm+ | 0.031″ – 0.047″+ | Heavier gauge, providing superior strength, rigidity, and impact resistance. Ideal for industrial buildings, large-span roofing, areas exposed to harsh weather conditions, or heavy snow loads. | Higher |

Choosing the correct aluminium roofing sheet thickness is crucial for ensuring the structural integrity and longevity of your roofing system.

The specific aluminium alloy used in the manufacturing of the aluminum roofing sheet significantly affects its mechanical properties, including its strength, formability, and corrosion resistance. Different alloys are chosen based on the desired performance characteristics and budget.

| Alloy Series | Common Alloys | Characteristics | Price Impact | Typical Roofing Uses |

|---|---|---|---|---|

| 1000 Series (Pure Al) | 1050, 1100 | Commercially pure aluminum. Excellent corrosion resistance, high formability, good thermal/electrical conductivity. Relatively soft. | Lower | Flashing, decorative elements, or less demanding residential roofing applications. |

| 3000 Series (Al-Mn) | 3003, 3004, 3105 | Moderate strength, good workability, excellent corrosion resistance. Stronger than 1000 series, making 3003 aluminium alloy very common. | Medium | General purpose residential and commercial aluminium roofing sheet, aluminium cladding. |

| 5000 Series (Al-Mg) | 5005, 5052, 5754 | Higher strength than 1000/3000 series, excellent corrosion resistance, especially in marine environments. Good weldability. | Higher | Coastal properties, high-wind areas, industrial roofing where superior durability is required. |

Proper packaging is vital for protecting aluminum roofing sheet during transit and storage, preventing damage such as scratches, dents, or corrosion. While packaging adds to the overall cost, it’s a worthwhile investment to ensure the material arrives in pristine condition.

| Packaging Component | Purpose |

|---|---|

| Plastic Film/Paper Interleaving | Placed between individual sheets to prevent surface scratching and abrasion during stacking and movement. |

| Kraft Paper/Waterproof Film Wrap | Entire bundles of sheets are wrapped in moisture-resistant materials to protect against humidity, rain, and oxidation, crucial for long-distance or overseas shipping. |

| Edge Protectors | Cardboard or plastic protectors placed on the corners and edges of bundles to prevent bending or denting during handling. |

| Steel Strapping | Securely bundles the sheets to prevent shifting, unraveling, and maintain integrity during transit. |

| Wooden Pallets/Skids | Sheets are stacked on fumigated wooden pallets or skids, facilitating forklift handling and ensuring stability during loading/unloading and storage. |

| Wooden Crates/Boxes | For maximum protection, especially for overseas shipping, delicate profiles, or highly valued color coated aluminum roofing sheet. Provides a robust outer shell. |

Reputable suppliers prioritize robust aluminium roofing sheet packaging to minimize transit damage.

| Factor | Influence on Price |

|---|---|

| Thickness & Size | Thicker and longer sheets cost more |

| Alloy Type | 5052 > 3003 > 1050/1100 |

| Surface Finish | Coated > Embossed > Plain |

| Order Quantity | Larger quantity = lower price per unit |

Estimated Price Range:

| Feature | Aluminum Roofing | Asphalt Shingles |

|---|---|---|

| Lifespan | 40–50+ years | 15–20 years |

| Weight | Lightweight | Heavy |

| Maintenance | Low | Moderate |

| Environmental Impact | Recyclable | Less eco-friendly |

| Cost Over Time | Cost-effective | Frequent replacement needed |

✅ Aluminum roofing has a higher upfront cost but offers better ROI over time.

The price of a sheet of aluminum roof varies significantly based on several factors, including:

Due to these variables, it’s difficult to give an exact per-sheet price without specific dimensions and specifications. However, generally, the raw material cost for aluminum roofing sheet typically ranges from $2.50 to $7.00 per square foot for the material alone, not including installation. For a rough estimate, a standard 3ft x 12ft (about 36 sq ft) sheet might cost anywhere from $90 to $250 or more for the sheet itself, depending heavily on the aforementioned factors. It is always best to request a direct quote from suppliers for your specific project.

While aluminum roofing sheet offers many benefits, it does have a few considerations:

Is aluminum roofing cheaper than shingles? No, generally, aluminum roofing has a higher upfront installation cost compared to asphalt shingles. A typical asphalt shingle roof might cost $4.50 – $7.50 per square foot installed, while an aluminum roofing sheet installation could range from $9.00 – $18.00+ per square foot installed.

However, it’s crucial to consider the life cycle cost. While more expensive initially, aluminum roofing offers:

When spread over its extended lifespan and factoring in potential energy savings, aluminum roofing often proves to be a more cost-effective investment in the long run.

Is aluminium sheet good for roofing? Absolutely, aluminum sheet is an excellent material for roofing due to a comprehensive list of benefits:

| Our Strength | Your Benefit |

|---|---|

| Own Factory | Direct prices, fast production |

| Wide Alloy Options | Meets various project needs |

| Export Experience | 10+ years in global markets |

| Customization Available | Size, color, embossing, and coil-to-sheet |

| Global Logistics Support | Efficient delivery, complete documentation |

The robust nature and numerous benefits of aluminum roofing sheet make it suitable for a wide range of applications:

| Material | Price per sq.ft | Lifespan | Maintenance | Best For |

|---|---|---|---|---|

| Aluminum Sheet | $3-$8 | 50+ years | Low | Long-term value |

| Asphalt Shingles | $1.50-$5.50 | 15-25 years | Moderate | Budget projects |

| Steel Roofing | $4-$10 | 40-70 years | Moderate | Industrial use |

| Clay Tiles | $10-$20 | 100+ years | High | Premium homes |

| Advantages | Disadvantages |

|---|---|

| ✅ Lightweight (1/3 weight of steel) | ❌ Higher initial cost |

| ✅ Corrosion-resistant | ❌ Can dent from impacts |

| ✅ Fireproof (Class A rating) | ❌ Noisier in rain |

| ✅ Low maintenance | ❌ Requires professional install |

| ✅ 100% recyclable | ❌ Thermal expansion/contraction |

| Alloy | Strength | Corrosion Resistance | Best For | Price Level |

|---|---|---|---|---|

| AA3003 | Medium | Excellent | Residential roofs | $ |

| AA5052 | High | Exceptional | Coastal areas | $$ |

| AA6061 | Very High | Good | Structural applications | $$$ |

| Factor | Requirement |

|---|---|

| Underlayment | Required (synthetic recommended) |

| Fasteners | Aluminum or stainless steel |

| Slope | Minimum 3:12 pitch |

| Tools | Metal-cutting shears, drill |

| Professional Help | Recommended for complex roofs |

| Task | Frequency |

|---|---|

| Visual inspection | Bi-annually |

| Cleaning | As needed (2-3 years) |

| Fastener check | After severe weather |

| Gutter cleaning | Seasonally |

| Coating inspection | Every 5-7 years |

| Question | Answer |

|---|---|

| How much does aluminum roofing cost? | $3-$8 per sq.ft installed |

| Is aluminum better than steel roofing? | Lighter and more corrosion-resistant |

| Can I walk on aluminum roofing? | Yes, with proper footwear and caution |

| Does aluminum roofing rust? | No, it forms protective oxide layer |

| What color options exist? | Wide range available through coatings |

Aluminum roofing sheet represents a significant investment that offers exceptional long-term value. While its initial price might be higher than some traditional options, its unparalleled longevity, superior corrosion resistance, lightweight nature, fire resistance, and energy efficiency make it a highly cost-effective choice over its lifespan. By understanding the factors influencing its thickness, alloy, and classification, you can make an informed decision to select the perfect aluminum roofing sheet for your project, ensuring a durable, beautiful, and sustainable roof for decades to come.