Phone:

(701)814-6992

Physical address:

6296 Donnelly Plaza

Ratkeville, Bahamas.

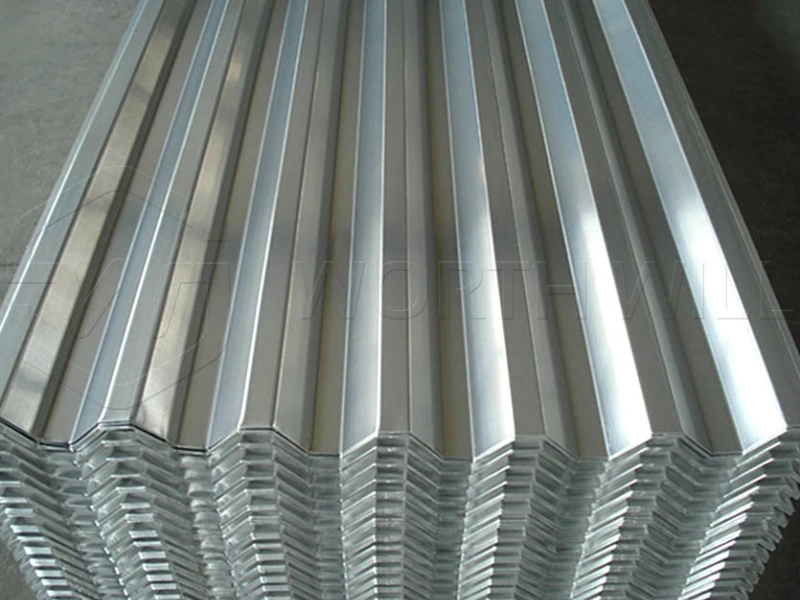

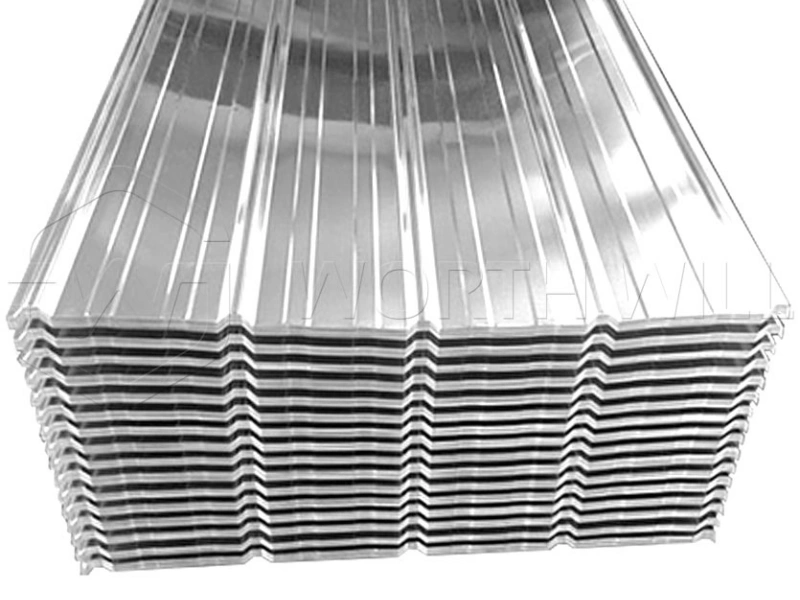

Aluminium roofing sheet is a popular choice for building roofs because of its durability, lightweight properties, and resistance to corrosion. This article will help you understand aluminum roofing sheets better, including their classification, thickness, alloys, and packaging. We will also explore their applications and advantages in simple language for easy understanding.

Aluminium roofing sheets can be classified based on their type and specifications. Here are some common types with their digital specifications:

| Type | Width (mm) | Length (mm) | Thickness (mm) | Alloy |

|---|---|---|---|---|

| Corrugated Sheet | 762 | 1830-6000 | 0.4 – 0.7 | 3003 |

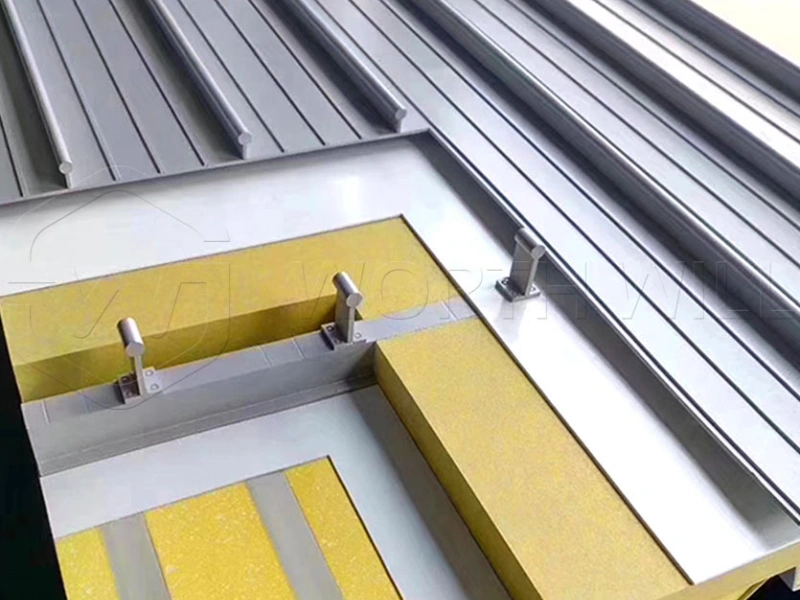

| Standing Seam Panel | 600 – 800 | Custom | 0.5 – 0.7 | 5005 |

| Smooth Sheet | 1000 – 1250 | 2000-6100 | 0.4 – 1.2 | 1100 |

| R-Panel | 914 | 2000-6000 | 0.5 – 0.7 | 3003 |

Thickness is an essential factor for roofing sheets because it affects strength and durability. The typical thickness for aluminum roofing sheets ranges from 0.4mm to 1.2mm. Here’s a simple breakdown:

Different aluminum alloys provide varied benefits such as strength, corrosion resistance, and flexibility. Common alloys include:

| Alloy | Description | Applications |

|---|---|---|

| 1100 | Pure aluminum, excellent corrosion resistance, easy to form | Domestic roofing, decorative roofs |

| 3003 | Aluminum-manganese alloy, good strength and corrosion resistance | Commercial roofing, industrial sheds |

| 5005 | Aluminum-magnesium alloy, high corrosion resistance and strength | Coastal buildings, marine environments |

Packaging is crucial to protect the sheets during transport and storage. Aluminum roofing sheets are typically packed in:

Proper packaging helps prevent scratches and damage, maintaining the quality of the sheets until arrival on site.

Aluminium roofing sheets are versatile and widely used in various construction settings. Key applications include:

| Feature | Detail |

|---|---|

| Types | Corrugated, Standing Seam, Smooth, R-Panel |

| Thickness | 0.4mm to 1.2mm |

| Common Alloys | 1100, 3003, 5005 |

| Packaging | Bundled with anti-corrosion wrapping, strapped, palletized |

| Applications | Residential, commercial, industrial, agricultural, coastal, temporary |

| Main Benefits | Lightweight, corrosion resistant, long-lasting, energy efficient, eco-friendly |

Q: How long does aluminum roofing last?

A: 50+ years with proper installation and maintenance

Q: Is aluminum roofing noisy during rain?

A: No, when properly installed with solid decking

Q: Can aluminum roofing be painted?

A: Yes, with appropriate metal paints

Q: How does it perform in hail storms?

A: Excellent impact resistance compared to other materials